With the rapid development of China's economic construction and the increasing scale of industrial production, explosion-proof issues have become more important. Explosion proof electrical products with diverse functions and varieties are widely used in various industries such as petroleum, chemical, and coal. Whether explosion-proof electrical appliances can operate stably and safely in various hazardous and explosive environments during use requires strict explosion-proof testing before leaving the factory. Zhongnuo Testing has rich experience in product design and testing in the field of explosion-proof. The following is a basic understanding of explosive gas and dust environments.

Gas/vapor type

Combustible substances: In explosion-proof technology, they refer to substances (including gases, liquids, and solids) that are inherently flammable and can produce flammable gases, vapors, or mist. Combustible liquids are further divided into flammable liquids and flammable liquids.

For example:

Gas category: hydrogen, methane, ethylene, acetylene, etc;

Liquids: petroleum (automotive oil), ethanol, monthly liquefied petroleum gas, etc.

Explosive substances refer to mixtures of combustible substances and air.

Several main parameters of explosive gas (vapor) mixtures:

(1) Flash point

Flash point refers to the minimum liquid temperature at which the amount of liquid that can be turned into vapor can form a combustible gas mixture under standard conditions.

The lower the flash point of a liquid, the easier it is to evaporate; The higher the ambient temperature or operating temperature is above the flash point, the faster the liquid volatilization rate, and it is highly likely to form an explosive hazardous environment. For example, the flash point of butane is -60 ℃, which not only evaporates steam in outdoor places in winter, but also quickly evaporates steam at room temperature.

The temperature of the surrounding environment or operating temperature is the main basis for affecting liquid evaporation.

(2) Explosion limit and range

The explosive limit refers to the minimum concentration (lower explosive limit) or maximum concentration (upper explosive limit) that can cause an explosion in a mixture of combustible gases (vapors) and air. The concentration range between the lower and upper explosive limits is called the explosive range.

The larger the explosion range, the greater the chance of forming an explosive mixture; The lower the lower the explosive limit, the easier it is for the conditions to form an explosion.

(3) Relative density

Density refers to the mass of a substance per unit volume. Relative density refers to the ratio of combustible gas (vapor) to air density (air is 1).

Relative density is an important basis for studying the diffusion range of explosive mixtures. Flammable gases (vapors) that are lighter than air will diffuse to the upper area of the surrounding space, while combustible gases (vapors) that are heavier than air will remain in the lower area of the surrounding space.

(4) The ignition temperature of explosive mixtures

The minimum temperature of the hot surface required to ignite an explosive mixture.

(5) The level of explosive gas

The level of explosive gases is convenient for the manufacture of Class II explosion-proof electrical equipment and intrinsic safety electrical equipment, and is divided into three levels: IIA, IIB, and IIC based on their characteristics. They are divided based on the maximum test safety gap MESG of gas/vapor and the minimum ignition current ratio MIC.

Dust type

Combustible dust: nominal size 500 μ Solid particles of m and below can be suspended in the air or precipitated by their own weight. They can burn or simmer in the air and form explosive mixtures with the air under atmospheric pressure and room temperature conditions.

Non conductive dust: resistivity greater than 1 × Combustible dust of 103 Ω· m.

Conductive dust: resistivity equal to or less than 1 × Combustible dust of 103 Ω· m.

Combustible flying flocs: nominal size greater than 500 μ m. Combustible solid substances, including fibers, that can be suspended in the air or precipitated by their own weight. For example: artificial fibers, cotton and linen, etc.

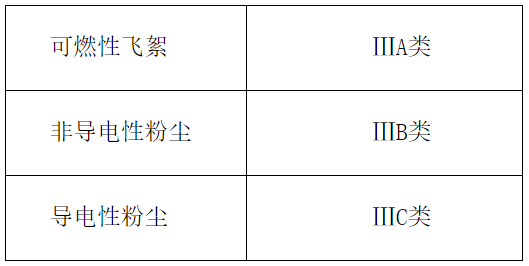

In GB3836.1-2010 "Explosive Atmospheres Part 1: General Requirements for Equipment", the following classifications are made based on the nature and hazard level of combustible dust:

Igniting temperature of dust layer: The minimum temperature at which a dust layer of specified thickness ignites on a hot surface.

The ignition temperature (MITL) of the dust layer is determined by placing the dust layer on a hot plate at different temperatures under standard atmospheric pressure and room temperature conditions, and measuring the temperature rise of the dust. The dust temperature exceeds the minimum hot plate temperature of 20K above the hot plate temperature.

The minimum ignition temperature of dust clouds: the minimum ignition temperature of the inner wall of the furnace when the dust clouds contained in the air inside the furnace ignite.

The minimum ignition temperature (MITC) of dust clouds is determined according to the testing methods and equipment specified in GB12476.8-2010.

This temperature value is also a basis for selecting and designing dust explosion-proof electrical equipment.

The basic concept of explosion

Explosion is an acceleration reaction of combustion. It is a phenomenon in which combustible materials undergo chemical reactions in air or oxygen under the action of ignition source energy, causing an increase in temperature and releasing thermal radiation and light radiation. If the combustion speed accelerates sharply and the temperature rises sharply, causing the combustion products and surrounding air to expand violently, forming a huge explosive force and shock wave, and emitting strong light and sound, this is called an explosion.

Therefore, the occurrence of an explosion must simultaneously meet the following two conditions: (1) having sufficient combustible substances and concentrations within the explosion limit range; (2) An ignition source with sufficient energy; For example, sparks, arcs, and high temperatures.

Explosive hazardous environment refers to an environment where, under atmospheric conditions, a mixture of flammable substances and air is ignited and exploded, and combustion will spread to all unburned mixtures.

An explosion hazardous area refers to an explosion hazardous area where personnel are working.

The concept of release source

Release source refers to a location or point where combustible gases, mist, or liquids may be released into the atmosphere to form explosive mixtures.

Continuous release source:

Continuous or expected long-term release sources.

For example, handling the interior of containers, storage tanks that are open to the atmosphere, vapor spaces above oil (liquid) in storage tanks, and spaces below the horizontal plane.

First level release source:

During normal operation, it is expected that there may be periodic or occasional release sources.

For example, during normal operation of the equipment, flammable substances may be released from the seals of pumps, compressors, and valves; Sampling points that release substances into the atmosphere during normal operation.

Second level release source:

During normal operation, it is not expected to be released, and if released, it is only an occasional and short-term release source.

For example: flanges, pipe joints, connectors; It is impossible to release the seals, safety valves, and exhaust holes of pumps, compressors, and valves during normal operation.

Explosion hazard area

The basis for the classification of explosive hazardous areas (gas/vapor) in China is:

GB3836.14-2000 "Electrical Equipment for Explosive Gas Environments Part 14: Classification of Hazardous Areas" GB50058-1992 "Design Code for Electrical Equipment in Explosive and Fire Hazardous Environments"

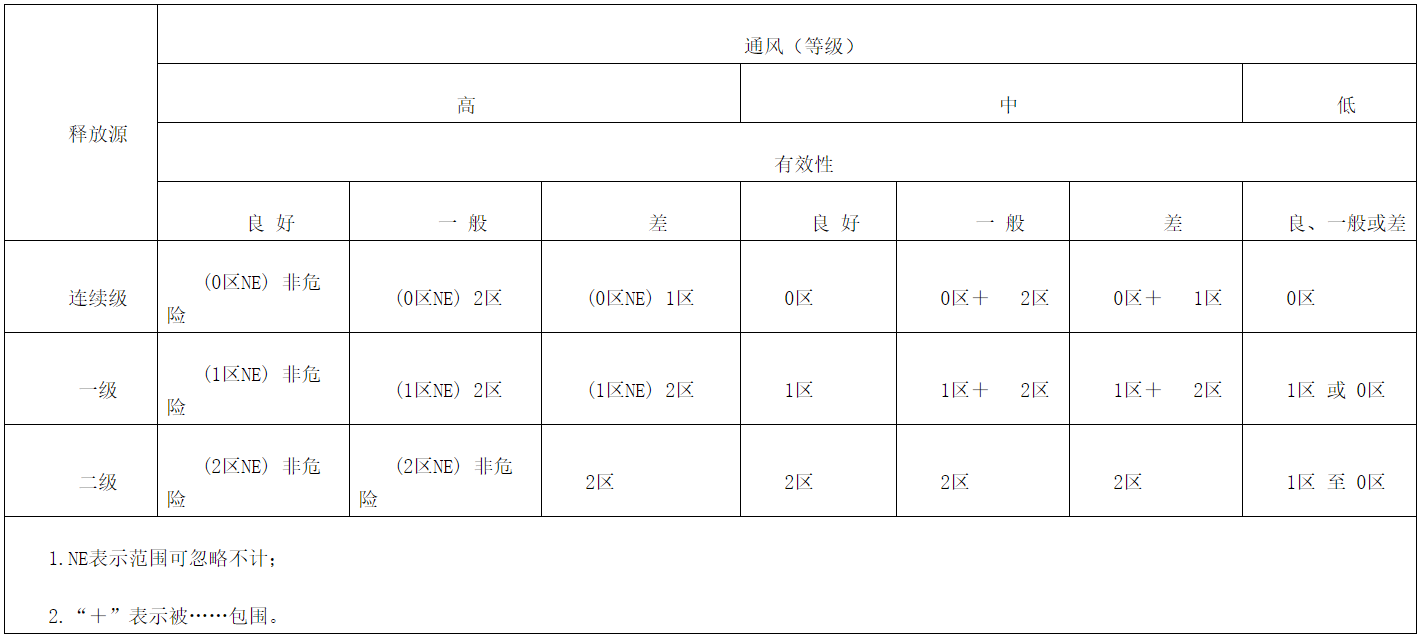

According to the frequency and duration of explosive gas (vapor) environments, hazardous areas are divided into the following areas.

Zone 0: Places where explosive gas environments occur continuously or exist for a long time.

Zone 1: Places where explosive gas environments may occur during normal operation.

Zone 2: During normal operation, explosive gas environments are unlikely to occur, and if they do, they may occur occasionally and only exist for a short period of time.

The classification of hazardous areas for explosive gases/vapors is determined based on the nature of the release source.

In principle, in the absence of any external conditions, a zero zone should be formed around the continuous release source; Zone 1 is formed around the first level release source; Two zones are formed around the second level release source.

Ventilation, also known as air flow, allows fresh air to replace the surrounding atmosphere of the release source to promote the escape of combustible gases. Proper ventilation rate can also avoid the persistence of explosive gas environments and affect the type of area.

Ventilation form: A) Natural ventilation; B) Artificial ventilation: overall or local ventilation.

In outdoor areas, natural ventilation usually plays an important role in dissipating any explosive environment that may occur.

Artificial ventilation: For example, using ventilation fans or exhaust devices. Artificial ventilation is mainly used in indoor or enclosed spaces. Divided into: Advanced Ventilation (VH); There are three types of ventilation: intermediate ventilation (VM) and low-level ventilation (VL).

The classification of hazardous areas for combustible dust is based on:

According to the frequency and duration of the occurrence of combustible dust environments, hazardous areas are divided into three zones. They are: Zone 20, Zone 21, and Zone 22.

Zone 20: Combustible dust continuously or frequently appears during normal operation, and its quantity is sufficient to form a mixture of combustible dust and air, and/or may form uncontrollable and extremely thick places and containers.

Zone 21: During normal operation, there may be a sufficient amount of dust to form a combustible mixture of dust and air, but it is not classified as Zone 20.

Zone 22: Places where combustible dust clouds occasionally appear and only exist for a short period of time under abnormal conditions, or where combustible dust occasionally accumulates or may have a dust layer and produce combustible dust air mixtures.