Explosion proof electrical equipment has obtained a gas explosion proof certificate. Can it be directly used in combustible dust environments?

Is the gas explosion-proof level high or the dust explosion-proof level high? What's the difference between the two?

Do non electrical equipment such as reducers and brakes used in explosive environments require explosion-proof certification?

Can gas explosion-proof motors be retrofitted with dust explosion-proof motors?

......

For explosion-proof, I believe everyone will encounter these problems.

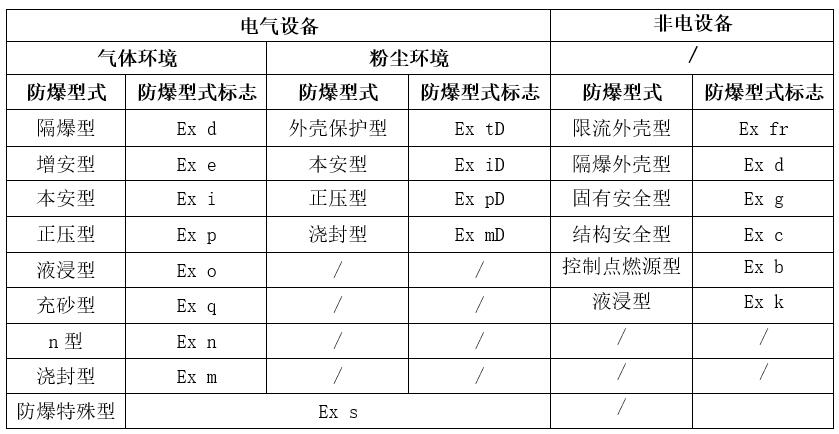

In fact, domestic explosion-proof certification has different classification methods based on the applicable environment of the product, electrical equipment characteristics, protection types, etc. For example, it can be divided into electrical explosion-proof certification and non electrical explosion-proof certification, and can also be divided into gas explosion-proof certification and dust explosion-proof certification.

Classification of explosion-proof certification

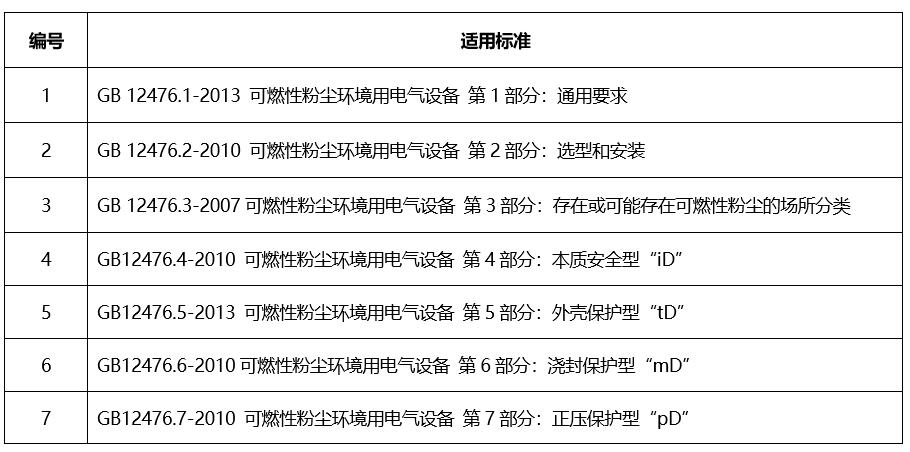

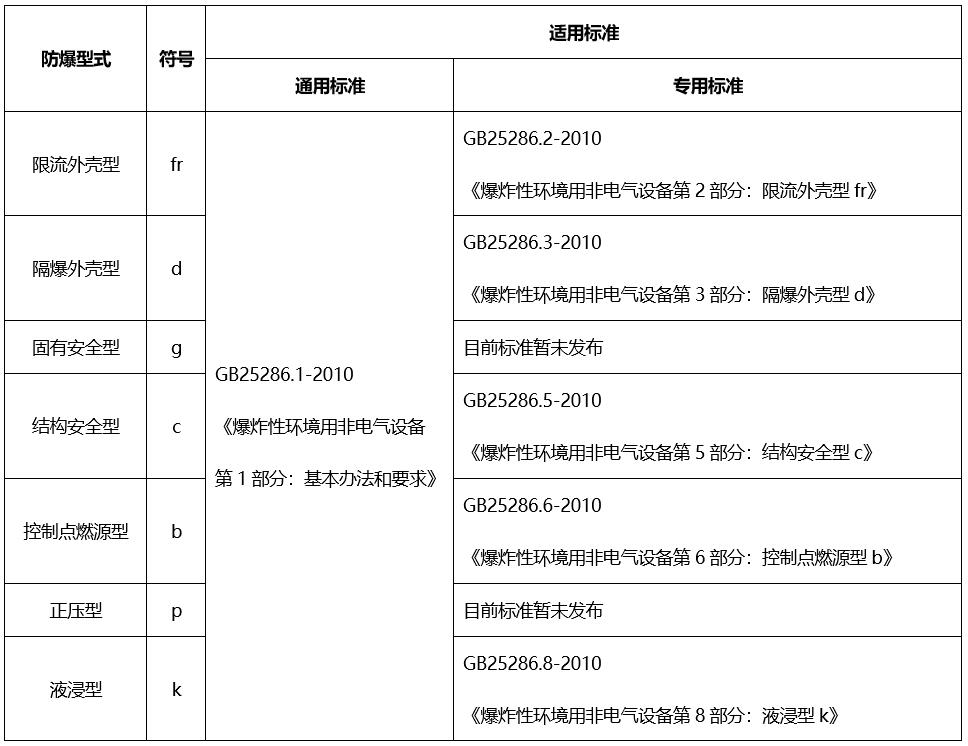

Classification of explosion-proof standards

Electrical equipment for explosive gas environments

Electrical equipment for combustible dust environments

Non electrical equipment for explosive environments

With the continuous expansion of the international market, domestic explosion-proof products are also constantly going out of the international market. The demand for ATEX certification in the EU market and IECEx certification in the international market is also increasing, and the applicable standards are also different from those in China. For more details, please pay attention to us.