Gas explosion-proof sign Ex d ib Ⅱ C T4 Gb

◆ Ex:Indicates that the electrical equipment meets one or more explosion-proof types listed in the Chinese GB3836 series explosion-proof standards and can be used in explosive hazardous areas.

◆ d:The protection type is explosion-proof

◆ ib:The protection type is intrinsically safe

Note: This explosion-proof sign includes two explosion-proof types, belonging to the composite type;

The GB3836 series explosion-proof standard specifies the following gas explosion-proof types:

d: Explosion proof type

e: Increased safety type

i: Intrinsic safety type

p: Positive pressure type

o: Liquid immersion type

n: N-type

q: Sand filled mold

m: Pouring and sealing type

◆ IIC:Electrical equipment used in explosive gas environments other than Class I coal mines that are prone to producing gas, commonly known as explosion-proof electrical equipment for factories. Class II electrical equipment is classified into three categories based on the minimum ignition spark energy of explosive gases: A, B, and C.

IIA: Representative gas is propane

IIB: Representative gas is ethylene

IIC: Representative gas is hydrogen gas

The IIC level is the highest and can be used as a usage bar for IIB and IIA devices; IIB can be used for the usage conditions of IIA equipment.

If electrical equipment is only used in a specific gas, write the chemical name or molecular formula of the gas in parentheses after symbol II, for example: "IIC (H2)";

※ If electrical equipment is used for a specific gas in addition to a special electrical equipment category, the chemical molecular formula should be added after the category symbol and separated by the symbol "", for example: "IIB H2"

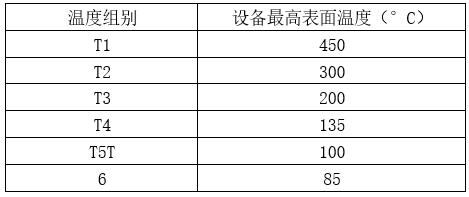

◆ T4:Temperature group, indicating that the highest surface temperature of the equipment does not exceed T4, which is 135 ° C.

The GB3836 series explosion-proof standard specifies 6 temperature groups, which are:

The lower the maximum temperature of the equipment, the less it can cause explosions of surrounding gases, and the better its safety performance. T6 devices can be used for the usage conditions of T5, T4, T3, T2, T1, and so on.

◆ Gb:Protection level of equipment

Equipment used in explosive gas environments with high levels of protection. During normal operation, expected or rare faults that occur are not ignition sources

Equipment used in explosive gas environments with a high level of protection. Not a ignition source under normal operation or expected fault conditions

Equipment used in Gc explosive gas environments has a "general" protection level. In normal operation, it is not a source of ignition, and additional protective measures can also be taken to ensure that effective ignition will not occur in the expected frequent occurrence of ignition sources (such as lamp failures)

※ In general:

Devices with Ga protection level can be used for Zone 0, Zone 1, and Zone 2

Gb protection level can be used for Zone 1 and Zone 2

Devices with Gc protection level can use Zone 2

※ China divides explosive gas hazardous areas into three zones: Zone 0, Zone 1, and Zone 2

→ Zone 0: A place where explosive gas mixtures exist continuously or for a long period of time under normal circumstances.

→ Zone 1: A place where explosive gas mixtures may occur under normal circumstances.

→ Zone 2: Places where explosive gas mixtures cannot occur under normal circumstances, or even if they do, they only exist for a short period of time.

Dust explosion-proof sign

Ex tD A21 IP65 T225 ° C T500320 ° C

◆ Ex:Indicates that the electrical equipment meets one or more explosion-proof types listed in the Chinese GB3836 series explosion-proof standards and can be used in explosive hazardous areas.

◆ tD:The protection type is shell protection type,

The GB12476 series of dust explosion-proof standards specify the following types of dust explosion-proof:

TD: Shell protection type

ID: Intrinsic Safety

PD: Positive pressure type

MD: Pouring and sealing type

A21:Class A electrical equipment for use in dust explosive environments in Zone 21

According to the frequency and duration of the occurrence of combustible dust environments, hazardous areas are divided into three zones. They are: Zone 20, Zone 21, and Zone 22.

※ Zone 20: Combustible dust continuously or frequently appears during normal operation, and its quantity is sufficient to form a mixture of combustible dust and air, and/or may form uncontrollable and extremely thick places and containers.

※ Zone 21: During normal operation, there may be a sufficient amount of dust to form a combustible mixture of dust and air, but it is not classified as Zone 20.

※ Zone 22: Places where combustible dust clouds occasionally appear and only exist for a short period of time under abnormal conditions, or where combustible dust occasionally accumulates or may have dust layers and produce combustible dust air mixtures.

◆ IP65:Shell protection level

◆ T225 ° CT500320 ° C: Maximum surface temperature; If temperature testing is conducted at a certain thickness of dust layer, the corresponding thickness values should also be marked separately.

The remaining rules are the same as those for equipment used in gas environments.