In the previous article, we provided a detailed introduction to the IP protection level requirements for explosion-proof equipment in combustible dust environments. textZhongnuo TestingNext, the IP protection level requirements for equipment used in explosive gas environments were introduced.

1. Enhanced safety electrical equipment "e"

(1) The protection level defined in GB/T4942.1-2006 and GB4208-2008 shall comply with the provisions in a) or b), except as otherwise specified in 4.9.2, 4.9.3 or Chapter 5.

a) The shell containing exposed live parts inside shall have a protection level of at least IP54;

b) The interior specified in 4.5 is only equipped with an insulated live component housing, with a minimum protection level of IP44.

(2) The casing of electrical equipment can be equipped with drainage holes or ventilation holes to prevent condensation from accumulating. The requirements related to equipment categories are as follows:

a) Class I equipment, with a protection level that meets the requirements of 2.1.1;

b) Class II equipment, drainage holes or ventilation holes can reduce the protection level provided by the casing according to 2.1.1. However, in the case of 2.1.1a), its protection level is not less than IP44, or in the case of 2.1.1b), its protection level is not less than IP44.

(3) If the enclosure is equipped with an intrinsically safe "i" circuit or system that complies with GB3836.4-2010, or components of an intrinsically safe circuit or system, a) the enclosure cover that allows contact with live non intrinsically safe circuits shall comply with the following:GB3836Warning signs shall be installed according to the requirements of a) in Table 12, or b) when the equipment casing is opened, all live parts of non intrinsically safe "i" circuits shall be equipped with isolation inner covers, with a protection level of at least IP30

2. Intrinsically safe electrical equipment "i"

The protection level of intrinsically safe equipment is determined according to the applicable location, and for equipment that meets the separation spacing in Table 5 of GB3836.4, the shell protection level shall not be less than IP20. Equipment that meets the separation spacing requirements of Appendix F of 3836.4 should achieve a level 2 pollution prevention level.

3. Positive pressure electrical equipment "p"

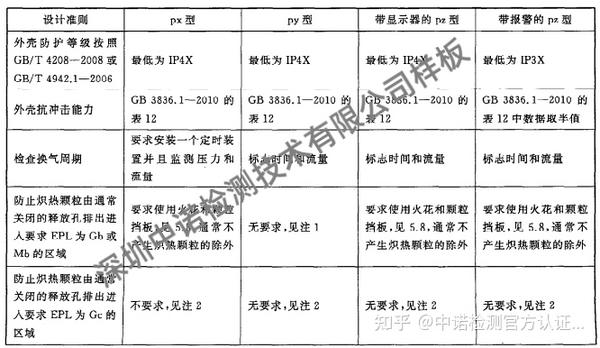

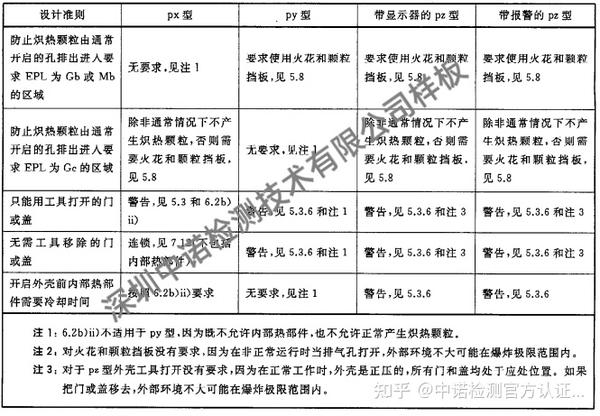

The positive pressure casing of positive pressure equipment should have a protection level that meets the following table (IP44 can be required on wet or coal dust mining working surfaces).

4. Liquid immersed electrical equipment "o"

The structure of Ex equipment should ensure sufficient protective liquid. According to the expected equipment protection level requirements, monitoring devices, indicators, or liquid level control safety devices with automatic shut-off switches can be used to ensure sufficient liquid without specific protection level requirements.

5. Sand filled electrical equipment "q"

(1) The enclosure of electrical equipment, electrical equipment components or Ex components protected by sand filled "q" should meet at least the IP54 protection level requirements specified in GB/T4208 under normal operating conditions, that is, when all openings are closed during normal use. If the protection level is IP5 or higher and the box is not airtight, the box should be equipped with a breathing device. The casing of the breathing device should at least meet the IP54 protection level requirements specified in GB/T4208. Protection tests should be conducted on empty boxes without filling. At the end of the waterproof test, there should be no visible water inside the box.

(2) If used only in clean and dry rooms, the protection level can be reduced to IP43. For this type of equipment, the symbol "X" should be added after the explosion-proof certificate number in accordance with the marking requirements of GB3836.1, and the special usage conditions specified in the explosion-proof certificate should specify the usage restrictions in detail.

(3) When the Ex components protected by sand filled "q" are installed in other explosion-proof types of enclosures that comply with GB3836.1, the protection level of the external enclosure should be at least IP54. If the installation position of the Ex component makes it impossible for it to be affected by any small amount of water that may enter the casing, there is no need to specify the protection level of the internal box.

6. Other explosion-proof types

Other explosion-proof types (such as explosion-proof, sealed, and spark free equipment) are not specifically guided in the standard, so the protection level is determined based on actual needs.

No platforms or individuals are allowed to plagiarize or repost!