Electrical equipment used in dust explosive hazardous areas should be selected according to the current national standard GB 12476.2-2010 "Electrical Equipment for Combustible Dust Environments Part 2: Selection and Installation". Explosion proof electrical equipment used in dust explosive environments has a similar structure to explosion-proof electrical equipment used in explosive mixed gas environments, which is not easily distinguishable in appearance, but is strictly prohibited from being used interchangeably (except for electrical equipment that has obtained dual explosion-proof certification for gas and dust). Explosion proof electrical equipment should be distinguished for suitability in dust explosive environments by the explosion-proof markings indicated on its nameplate.

Dust explosion-proof sign

Generally speaking, electrical equipment commonly used in combustible dust environments should use explosion-proof signs in accordance with Article 29 of GB 12476.1-2013 "Electrical Equipment for Combustible Dust Environments Part 1: General Requirements".

The commonly used explosion-proof types and their corresponding explosion-proof signs are as follows:

1Positive pressure protection type "pD"

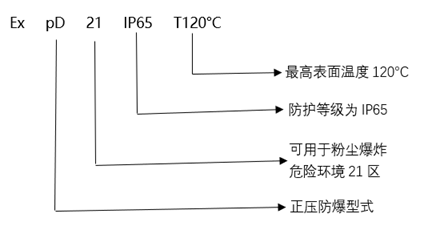

The principle of positive pressure protection type explosion-proof electrical equipment in the explosion-proof qualification certificate is to maintain an overvoltage inside the casing above the environment, in order to avoid the formation of explosive dust environment inside the casing. Its explosion-proof sign should at least have the Ex symbol; Explosion proof type code pD; The area where the equipment can be used; Shell protection level (IP code); Composition of the highest surface temperature value (℃). For example:

2Shell protection type "tD"

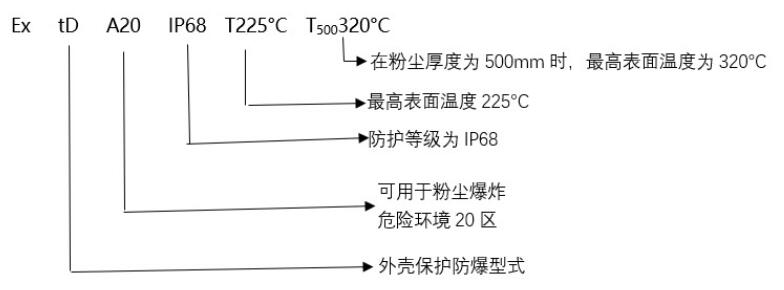

The principle of explosion-proof electrical equipment with shell protection in the explosion-proof qualification certificate is to prevent combustible dust from igniting by setting up a dustproof shell that can prevent all visible dust particles from entering or an shell that does not completely prevent dust from entering but takes measures to prevent it from entering enough to affect the safe operation of the equipment. The explosion-proof symbol should at least consist of the Ex symbol, explosion-proof type code tD, equipment usable area (prefixed with A or B), enclosure protection level (IP code), and maximum surface temperature value (° C), for example:

Two different types of shell protection "tD" are specified: Type A and Type B. These two types have the same level of protection.

The two types of A and B are universal, and the requirements for equipment selection/installation will not be confused. They only use different methods, and the main difference is:

3Intrinsically safe "iaD" and "ibD"

The explosion-proof types of intrinsically safe explosion-proof electrical equipment are divided into two types: iaD and ibD. It is achieved by limiting any electrical sparks or thermal effects generated by connecting wires inside the equipment and exposed to explosive environments, so that the energy generated is lower than that of electrical equipment that can cause ignition energy. Its explosion-proof sign should be marked with the Ex symbol; Explosion proof type code iaD or ibD; The area where the equipment can be used; Composition of the highest surface temperature value (℃). For example: Ex iaD 20 T120 ℃

4Pouring and sealing protection type "mD"

Sealing protection type refers to the electrical equipment that seals sparks or heating components that may ignite explosive environments into a composite, so that they can avoid igniting dust layers or dust clouds under operating or installation conditions. Its explosion-proof sign should be marked with the Ex symbol; Explosion proof type code mD; The area where the equipment can be used; Composition of the highest surface temperature value (℃). For example: Ex mD 20 T120 ℃

Some explosion-proof electrical equipment can be used in both dust explosion hazardous environments and explosive gas mixture environments. The explosion-proof label on its nameplate should have both explosion-proof labels suitable for combustible dust environments and two explosion-proof qualification certificates suitable for explosive gas mixture environments.

Service hotline: 18924609560 (same WeChat account)