Explosion proof packing boxes are widely used for sealing explosion-proof electrical products and cables, commonly including packing type cable entry devices and packing type conduit sealing devices.

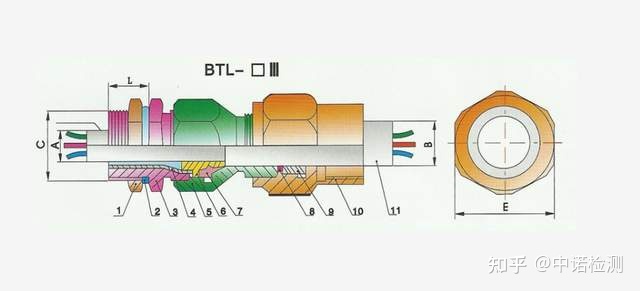

The filler type cable entry device is generally installed at the connection between the cable port and the explosion-proof equipment. The filler is directly inserted into the inner cavity and compacted with bolts to achieve the purpose of sealing. At the same time, it can prevent external grease, water stains, or some media from entering and interfering with the cable, which will affect the operation of explosion-proof equipment and affect its service life. It is generally suitable for places with harsh environments, such as offshore oil platforms, and equipment with high explosion-proof requirements, such as IIC explosion-proof products.

The packing type conduit sealing device is mainly used in the conduit wiring of explosion-proof equipment, which plays an isolation role at the joints of electrical circuits, preventing the transmission of explosive energy from one place to the entire electrical system. Common examples include isolation sealing boxes.

Regarding the sealing requirements for packing boxes, it is stipulated in C2.1.2 and C2.1.3 of GB3836.2-2010 that:

The minimum length of the filler during installation should be 20mm.

Manufacturers should specify:

——Sealed joints allow the use of cable cores with a maximum outer circle diameter of:

——The maximum number of core wires passed through the filler.

These specified values should ensure that at least 20% of the cross-sectional area along the 20mm length of the sealing packing is filled by the packing.

The cable entry device should be able to be assembled onto electrical equipment after the specified filling solidification period, and can be removed from the equipment without damaging the sealing of the filling.